The next generation IoT gateway solutions that will transform manufacturing

The use of intelligent manufacturing, digital transformation, and intelligent edge computing solutions enable manufacturers to increase productivity, decrease downtime and improve product quality. The deployment of edge computing solutions is among the most important contributors to the success of this transformation. These solutions form a bridge to connect Operational Technology (OT) and Information Technology (IT), while providing multiple advantages.

Lower latency

.png?width=284&name=N%C3%A9vtelen%20terv%20(44).png)

Manufacturers are expected to react promptly to customer requests by making available custom products and services on a global scale. Furthermore, in the case of time sensitive applications data collected from a wide range of devices has to be processed immediately to support fast decision-making. Intelligent edge computing solutions provide this on site, without having to send all the data from the equipment of the plant to the cloud for processing.

Data security

.png?width=265&name=N%C3%A9vtelen%20terv%20(57).png)

Sending sensitive data to the cloud is a risk from the perspective of both data and plant equipment. Multiple layers of security need to be implemented to ensure that data is securely transmitted from plant equipment to the cloud. Data processing using edge computing devices helps to prevent data security incidents and provides a better response time.

Independent remote operation

.png?width=284&name=N%C3%A9vtelen%20terv%20(45).png)

Edge computing platforms enable remote sites to decrease downtime and operate independently when the central system is unavailable. For example, if the cloud system is unavailable due to a network connection failure sites can continue to process and analyse data using on site processing capacities. Once the connection is re-established processed data can be sent to the cloud for long-term storage.

Lower data transfer costs

.png?width=274&height=290&name=N%C3%A9vtelen%20terv%20m%C3%A1solata%20(3).png)

The transfer of large quantities of data directly to cloud servers can generate excessive costs. Transferring data on a daily basis can generate unsustainable costs in the long run.

Manufacturers seek optimized IT solutions for their industrial automatization applications that enable intelligent processing of large quantities of data collected from sensors and plant monitors so that only critical and pre-processed, summarized data is sent to the cloud. Such solutions are based on small, resilient, industrial grade, small energy consumption, ARM-based computers that make edge computing more reliable and cost effective.

Advantages of using ARM-based Linux IIoT gateway solutions

ARM-based Linux IIoT gateway solutions provide industrial grade security, management, performance and reliability with upgrade options. These solutions generally provide the following hardware, OS, and software functions to deliver an optimized edge computing solution for IoT application.

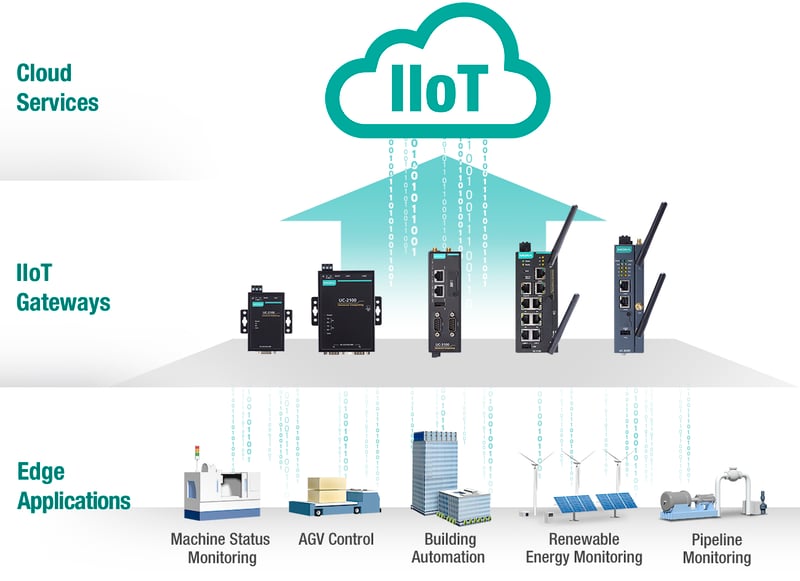

Ready to use Moxa wireless IIoT gateway solutions

The Moxa UC series of industrial IoT gateway solutions are industrial grade ARM-based processing platforms ready for wireless use that were designed to operate reliably in an extended temperature range (-40 to +85 °C). These gateways are built on the Arm® Cortex®-A processor and run Moxa Industrial Linux (MIL) to meet the demand for extended lifecycle IT systems of such industries as manufacturing automation, solar and wind power, water and wastewater management, the oil and gas industry and transportation. Key advantages include the following:

- Industrial grade Linux

- Low energy consumption

- Secure platform (TPM)

- A wide range of supported interfaces and protocols

- Simple connectivity provided by edge and cloud solutions

REQUEST INFORMATION

Gergely Kovács, senior software developer. A truly creative coder, Gergely has been developing a wide variety of applications at Com-Forth since 2004. These include the protocol conversion applications based on MOXA embedded machines, the complex SCADA pharmaceutical plant machine management project, and the frontend of the daily capacity planning system. He is equally at home working with legacy VBA and the most innovative Angular 7. Besides György Melegh, he is our MOXA support engineer. He primarily assists our customers with embedded programming projects.

Com-Forth needs the contact information you provide to us to contact you about our products and services. You may unsubscribe from these communications at any time. For information on how to unsubscribe, as well as our privacy practices and commitment to protecting your privacy, please review our Privacy Policy.

.png)

.png)

.png)

.png)