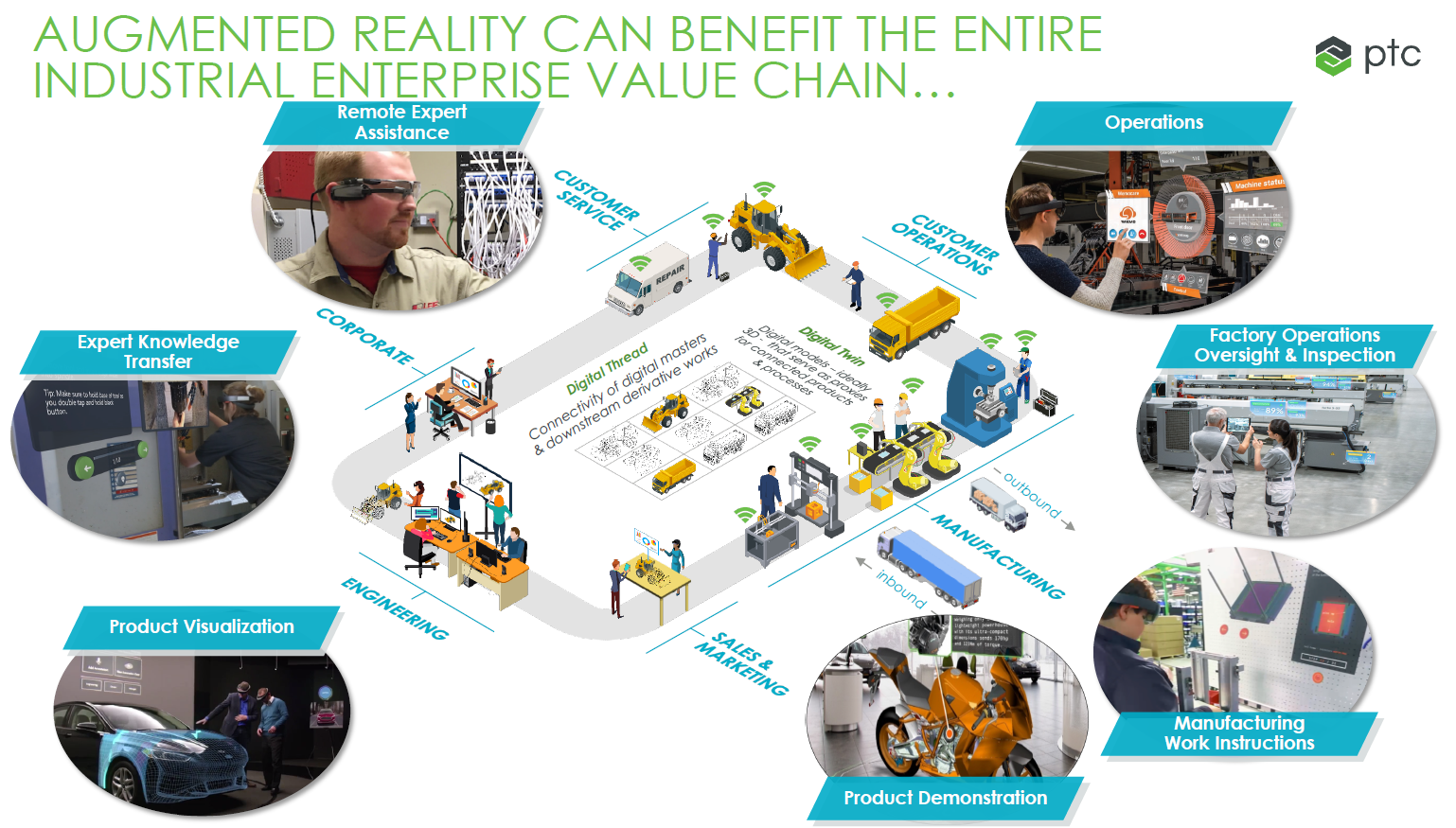

Although the industrial use of Augmented Reality (AR) is a relatively new technology, it has proved to be a success in several different fields.

These may include the following:

Due to the aging society a great many industrial workers will retire in the near future. It would require considerable time and cost to document their knowledge.

Using AR technology, processes and manufacturing instructions can be documented 10 times faster than conventional, paper-based solutions.

Labour shortages and increasing fluctuation result in higher training costs for manufacturing companies. According to a survey conducted by Deloitte, companies in the world on average spend USD 1,200 on the training of each employee.

Xerox found that using AR technology can reduce the induction time requirement by 50% and has a beneficial effect on fluctuation, as well.

Defective products and rework can amount up to 2% of net sales.

According to a study conducted by the University of Iowa, the use of AR technologies may reduce the defect rate by 50%. Siemens’ figures show that quality can be increased by 20–25%.

If engineers and experts need to travel between sites and within sites, this represents a waste of time and can generate significant travel and other costs (for example extra time fees).

An easy-to-use AR solution, for example Vuforia Chalk, can help you solve this issue. Moreover, shorter fault detection and intervention times lead to considerably better machine availability and shorter downtime.

The process engineer, maintenance technician, or system operations IT expert can provide real time support for the operator or technician using a smartphone or a tablet. Augmented reality helps them to see the same as what the actual employee physically performing the action sees.

The necessary steps can be written / drawn on the screen of the portable device. The instructions received can be saved for reuse when similar jobs need to be done in the future.

This enables the optimal utilization of working hours of experts, while travel and extra time expenses can be significantly reduced.

The Vuforia Chalk application enables the expert providing remote assistance to “pause” the live feed, write or draw explanations or instructions on the screen, and to guide the on-site technician by voice. If the affected area is dark, the expert can remotely switch on the light on the technician’s device.

The drawn or written instructions are “connected” to the actual objects and will not move even if the technician moves the camera.

The 3D digital manufacturing, assembly, and packaging instructions are connected to the physical objects and show the milestones of the process using a step-by-step approach. The solution can be enhanced with real time IoT data.

Thanks to the above, Vuforia Studio enables operators to work more precisely, effectively and autonomously compared to traditional paper-based instructions. Simultaneously, the training time requirement can be reduced. It is also important that the displayed real time IoT, production or sensor data show the parameters of the actual work piece. This helps to prevent errors.

By increasing productivity and reducing errors, these features improve quality.

Vuforia Studio is an effective tool to create 3D content for manufacturing, assembly, packaging, disassembly and training processes.

Visualizations can be connected to real time IoT data.

Róbert Herczku, our business development expert works with countless end users, system integrators and reseller partners to ensure that they choose the MOXA hardware for their application that offers the best value for money. Róbert joined us in February 2016 and primarily assists partners in substations, solar power stations, transportation, and security technology projects and other infrastructure investments.

Com-Forth needs the contact information you provide to us to contact you about our products and services. You may unsubscribe from these communications at any time. For information on how to unsubscribe, as well as our privacy practices and commitment to protecting your privacy, please review our Privacy Policy.