Fast and no-code development of web-based operator interfaces

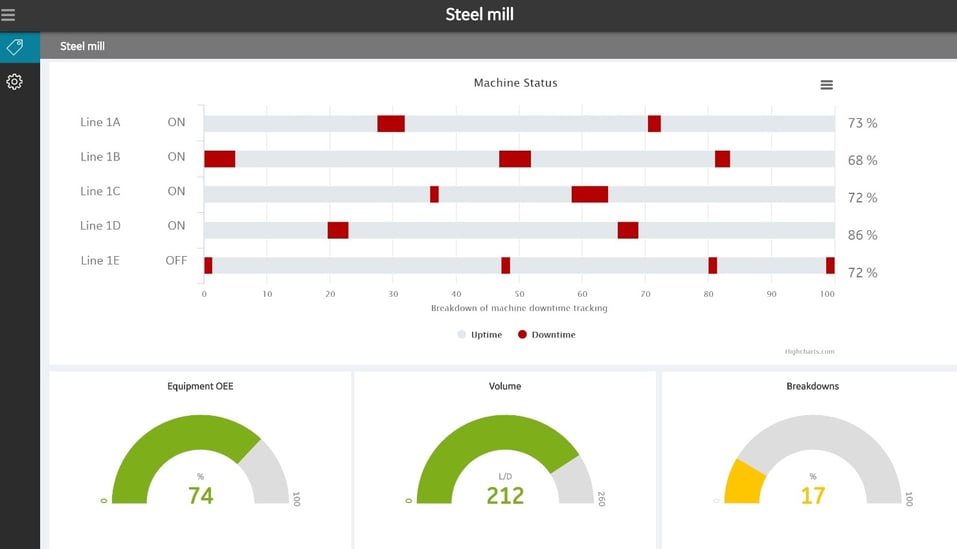

Proficy Operations Hub developed by GE Vernova is a summary and display tool for industrial applications that combine quick application development with detailed visualizations. The system supports improved decision-making and shorter response times in the case of process or requirement changes with simple configuration options.

Proficy Operations Hub enables system integrators and in-house engineering teams to use high performance, no-code development tools to build web-based applications that can be connected to GE Vernova software and other typical Industry 4.0 data sources such as databases and other control systems. No-code tools facilities the inclusion of multiple non- developer users in the creation of customized visualizations at the same time. This accelerates development and helps to lower costs.

The system provides connectors to various data sources. It also provides storage capacities for the data necessary for initial analysis and visualizations. This enables organizations to gain a unique insight into process flows and the details of production. This in turn is an essential step on the path towards digital transformation.

Accelerated development of advanced web applications

In order to facilitate the implementation of responsive operator visualizations Proficy Operations Hub provides a collection of pre-defined and pre-configured control elements to enable non-developer contributors to quickly create and design visualizations. Data sources and entities of the connected devices can be easily defined and converted to actionable information using data query capabilities. The drag and drop interface of visualizations enables easy planning and configuration of visual elements. To create a data connection all you need to do is to configure a query or a data source for the respective element.

Results

- Visualization and fast development of web-based manufacturing parameters

- Centralized visualization ensures faster response time and informed decisions

- Lower cost and shorter market introduction time of web-based operational application development

- Lower maintenance costs of centralized web applications

- Information is available anytime and anywhere due to responsive design

Instant access to information

Responsive design helps to create applications that can display information on a PC, tablet, or smart phone, giving access to production data and manufacturing parameters anytime and anywhere.

Actionable information collection and visualization

You can use the predefined control element collection to easily create charts, tables, diagrams, figures, videos, maps and so on. Proficy Operations Hub also offers manual data entry control elements for user input to execute operations and return data and commands to the connected sites. Operators can open additional data related interfaces, modify context and manually input data.

Proficy Operations Hub enables everyone to build web-based applications using no-code development tools.

Save time with ready to use clients and centralized administration

Using web technology, Proficy Operations Hub enables you to save time on deployment and maintenance. Truly native web clients do not require installation. Deployment and maintenance have never been this simple.

A quick, automatic response

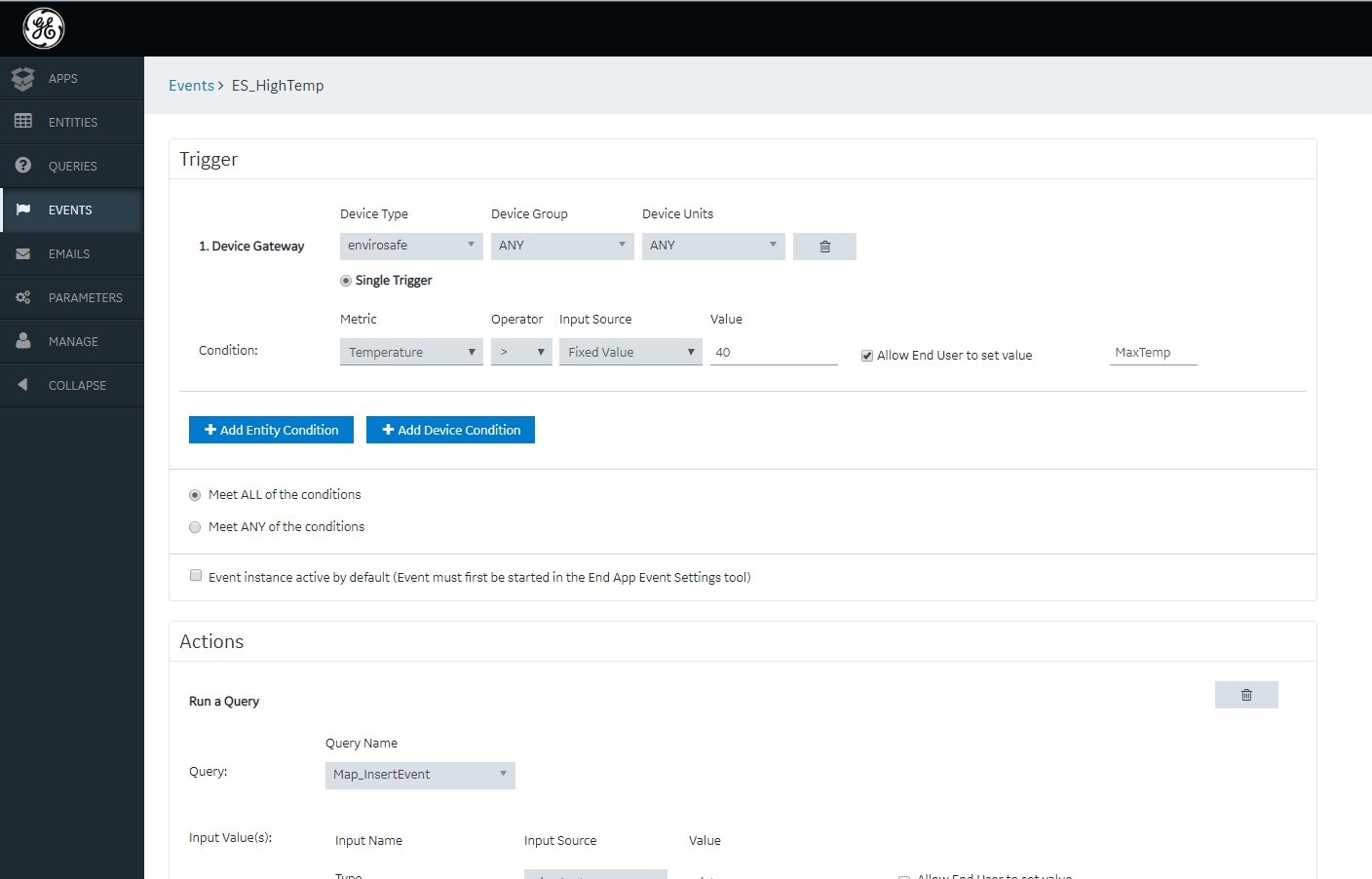

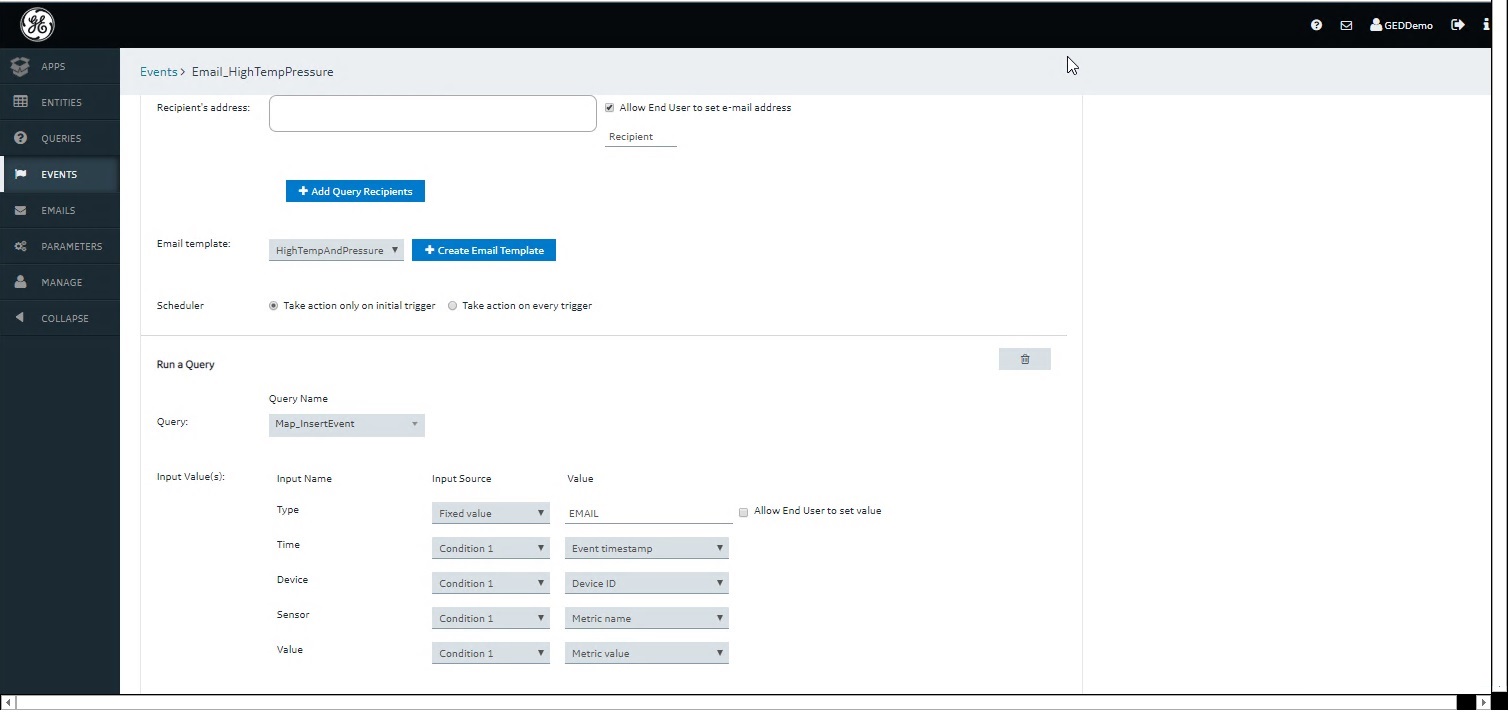

Proficy Operations Hub enables you to create automatized actions based on human or machine data. You can configure actions to query data or send emails or commands to devices connected to the system.

Features

- You can develop, manage and create applications that collect, display and prepare for analysis data received from devices or servers – without developer skills

- A user friendly interface with a rich predefined object library for developers

- Automatized operations based on the data stored in a common database

- Event-based operations: Send emails (including templates), run queries and send commands to devices

- Create entities and queries for relational databases

- The use of HTML5 and CSS3 languages ensures platform independence

- Applications are available on a PC and on mobile devices

- Application and data access control based on user roles

- Query types: Get, update, insert, delete

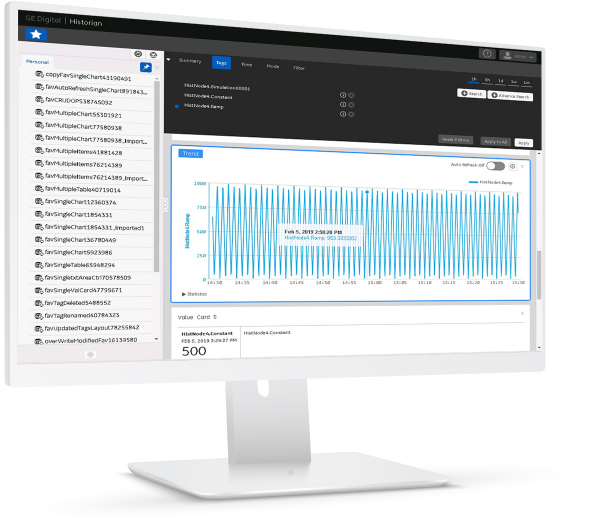

- Off-the-shelf trend analysis app to facilitate root cause analysis. KPI dashboard creation using historical data. A wide range of data analysis tools.

- Model and flat tag support

- Updated security: Support for Active Directory shared UAA

- User friendly WYSIWYG (What You See is What You Get) app elements, drag and drop configuration option

- ISA 18.2 and ISA 101 for enhanced operator productivity and security

- Integrated web-based technologies – cloud, Docker, mobility and collaboration tools

- Control elements:

- Input: Checkbox, radio button, combined list, text slider, switch, button, camera, text field

- Display: Text, figures, diagrams, charts, grids, data tables, maps, lists, measuring tools, indicators

- Layouts: Separators, holders, lines

- Connectivity

- Connectors:

- MQTT: A machine to machine protocol using a simplified publish / subscribe message transfer

- REST API (get support): Enables communication between web clients and servers

- Historian: Provides time stamp enabled data storage

- URL

- Planned connectors:

- Time Series, Proficy Plant Applications, iFIX, CIMPLICITY, Proficy Workflow, Proficy Batch Execution, OPC UA, relational databases

- Planned visualization content:

- Historian trend and alert analysis

- HMI control elements, Workflow control elements, Plant Applications control elements, measurement tools, diagram types (Pareto, histogram, event trends, heat map, radar, spider web)

Hardware requirements

Single server architecture:

- 64-bit, 4 cores CPU, 8 GB RAM, 100 Gb free disk space

Dual server architecture (recommended for production systems)

- 64-bit, 1 × 4 cores CPU, 8 GB RAM, 25 GB free disk space for the application server

- 64-bit, 1 × 4 cores CPU, 8 GB RAM, 100 GB free disk space for the database server.

- Actual disk space requirement depends on data volume needs

Software requirements

-

The latest version of Ubuntu Server 16.04 LTS for the platform server

- Preinstalled PostgreSQL v10.5 on the database server of the dual server system.

- The PostgreSQL database server can be installed on any supported operating system

You might also be interested in the following

How can Com-Forth help?

Our experts have extensive technical expertise and planning experience. They can help you at any stage of your project from requirement specification and complete system planning to the implementation of data connections and full-scale system execution. A wide variety of successfully implemented projects ensure that our engineers will be able to provide valuable help from project start to delivery.

REQUEST INFORMATION

Zoltán Misik, senior application developer engineer, joined Com-Forth Kft. in 2002. His primary fields are MES system development, installation, and operation. In addition, it is difficult to find a GE software that he has not yet had extensive project experience with, including the vast majority of legacy products.

Com-Forth needs the contact information you provide to us to contact you about our products and services. You may unsubscribe from these communications at any time. For information on how to unsubscribe, as well as our privacy practices and commitment to protecting your privacy, please review our Privacy Policy.